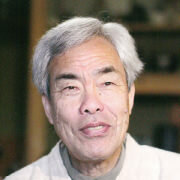

Hiroshi Suigetsu

ARTISTS & CRAFTSMEN AT ORYOKI

"The Suigetsu family has been associated with the development of Banko-Yaki for generations. Almost 300 years ago, the production of Banko ceramics began in the city of Yokkaichi, located southwest of Asahi in Mie Prefecture. Ceramic production is considered the outstanding traditional craft in the area. Suigetsu Kozaburo, the first master, was born in Yokkaichi in 1869. He began making teapots at a young age using a Banko made of wood, a wooden mold developed in the Edo period, laying the foundation for the Suigetsu kiln.

In 1901, Suigetsu Gen was born and not only followed in his father's footsteps but also became a significant representative of Yokkaichi and Japan's ceramic culture. Suigetsu Hiroshi, the current, third master, was born in 1944. His craftsmanship has been highly recognized in numerous exhibitions and many awards. He was already recognized as a "Traditional Craft Artist" in 1976, a highly respected classification in Japan, followed by 26 more awards. In 1990, his works were exhibited at the Emperor's enthronement ceremonies, and in 1999, the Crown Prince invited him to personally present his artworks. Some of his works were presented as gifts during state visits, such as in 2007 during the visit of Chancellor Merkel.

Hiroshi Suigetsu remains an active artisan. He is supported by his wife Kishiyo and his two sons Jun and Ushio. We are deeply honored that the Suigetsu family trusts Oryoki and allows us to present and offer their products."

"The Determination of Banko-Yaki" - Art for Eternity

Banko-Yaki has its origins in the Edo period (1603-1868). Nunami Rozan, a wealthy merchant, established a kiln in Kuwana to fire ceramics. Today, the kiln is located in the city of Asahi, which belongs to Mie Prefecture. Banko ceramic ware received its name from the idiomatic expression "Banko Fueki," which means "unchangeable forever." Nunami Rozan founded his hope on this promise, believing that the intricate works he created would be preserved for a long time and passed down from generation to generation.

The symbol of Banko-Yaki is the Japanese teapot "Shidei," which is made from high-quality, local, and very iron-rich clay, also called Shidei. The literal translation of Shidei

The literal translation of Shidei is "purple mud." Original Shidei teapots are fired without glaze, so that their luster and entire aesthetic improve with use, just like the taste of tea, which gains harmony and more flavor nuances when brewed in properly used and cared for teapots. This is naturally the main reason why teapots made of Banko-Yaki are highly esteemed among tea connoisseurs.

Sandblasting

The skill of the third Suigetsu master is sandblasting - which offers the possibility to create a variety of different patterns. Lightly scraping the surface of the purple clay turns it black. Scratching slightly harder and deeper into the clay reveals a gray color. The patterns created by the contrast of these three colors are both delicate and elegant, fascinating anyone who beholds them.