Cooking with cast iron at the highest level

THE CAST IRON MANUFACTURE OIGEN

Cast iron cookware is considered healthy and the best foundation for a good taste of food. They are appreciated not only by professional chefs, but also by hobby cooks who now understand their special properties.

In this article, you will learn what defines top quality in the production of cast iron pans, where the differences between differently manufactured cast iron pans lie, and what to look for when making a purchase.

Table of Contents

Inhaltsverzeichnis

What are the basic differences between cast iron pans? A question of coating Naked finish from OIGEN The best taste experience when cooking with cast iron Why should the OIGEN pan also be baked before use? Can lower quality cast iron pans be heated without contents? The non-stick effect. Why does food sometimes stick to the cast iron pan? What characterizes high-quality cast iron pans? A scientific insight A comparison of the heat transfer of OIGEN Naked Pan cast iron pans with conventional frying pansWhere are the fundamental differences in cast iron pans? A question of coating

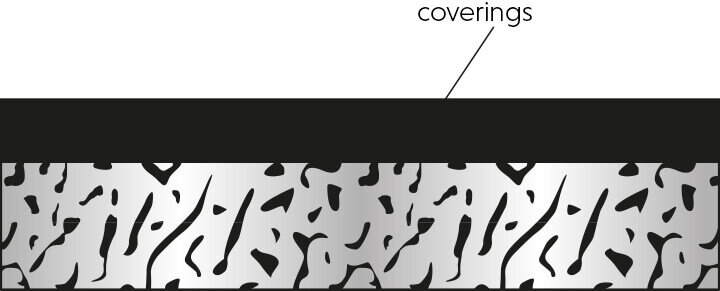

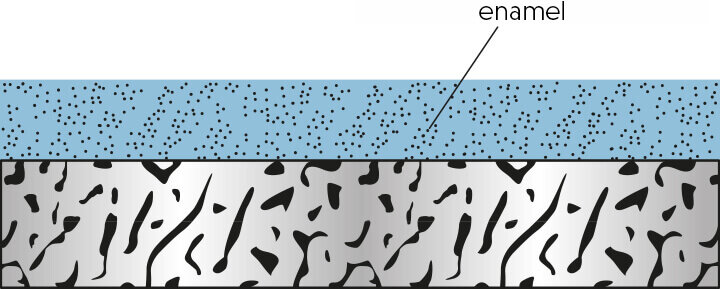

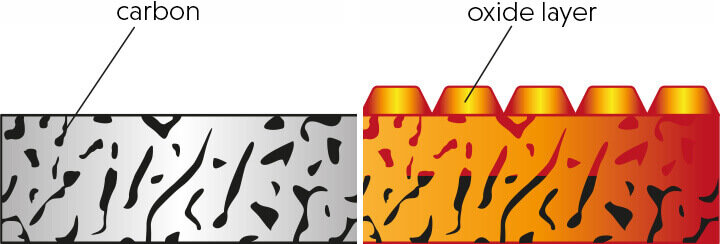

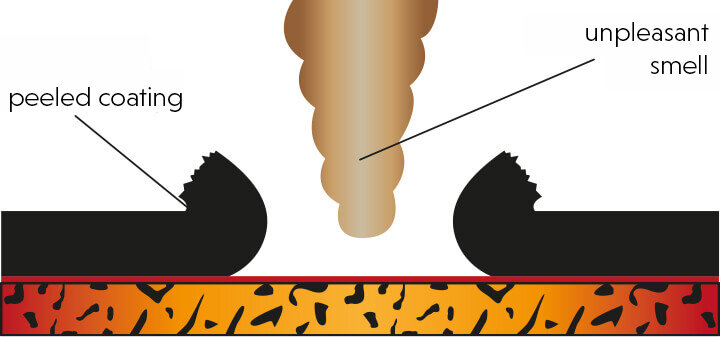

Cast iron contains carbon particles. Fresh cast iron has a unique iron smell and rusts very easily. To protect the pans from rust, there are various coatings. Cast iron pans with enamel coating undergo significant changes in their properties. The coating is created by baking powdered glass on a metal base. As a result, the food no longer comes into contact with the cast iron, but only with the enamel. Enamel pans are suitable for braising and stewing.

If one values the original properties of cast iron, it is advisable to opt for pans with a natural coating. Among other options, coatings with cashew resin and oils are available, but heat-resistant silicone is also used partially as a coating. However, there is yet another patented, natural method for coating cast iron pans, originating from the manufacturer OIGEN.

Naked-Finish by OIGEN

In this process, the cooled cast iron pans are reheated to between 800 – 900 °C. This forms a uniform, fine oxide film. In this process, the carbon particles on the surface of the cast iron are burnt off. The fine oxide film protects the cast iron from rust, without an artificial layer that could hinder heat transfer and radiant heat.

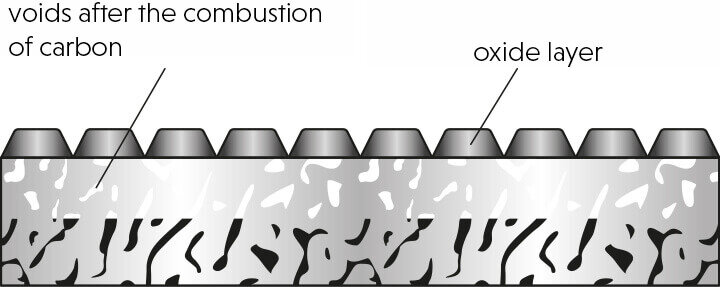

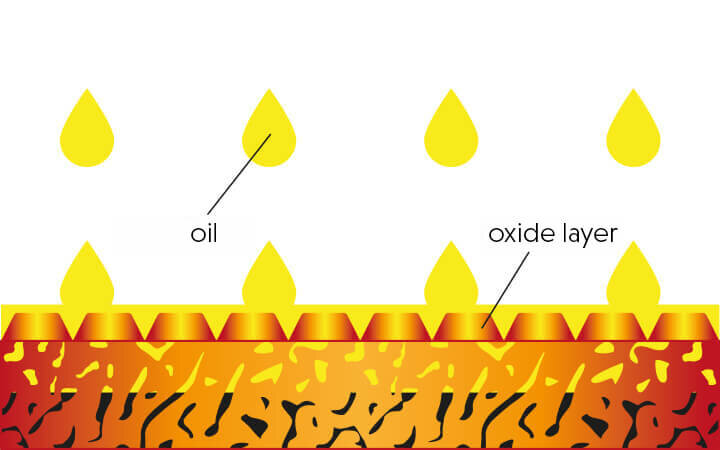

By burning off the carbon particles, the surface of OIGEN products becomes slightly more porous, allowing oil to be more absorbed. This achieves a better non-stick effect and, by omitting additives, an uncoated cast iron pan with excellent properties and an environmentally friendly premium OIGEN product. In this process, the pan obtains its typical gray color, which darkens again after multiple uses.

The Ultimate Cooking Experience with Cast Iron

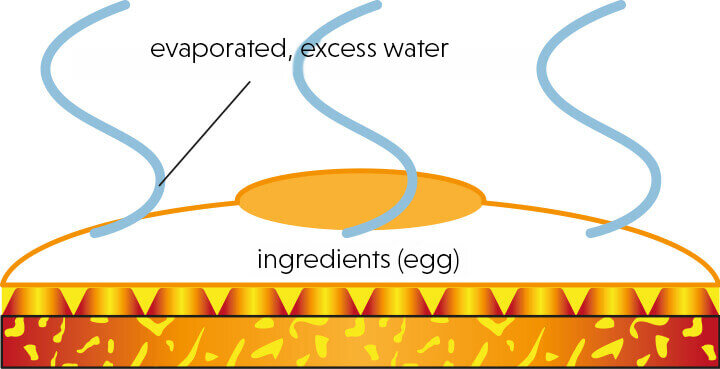

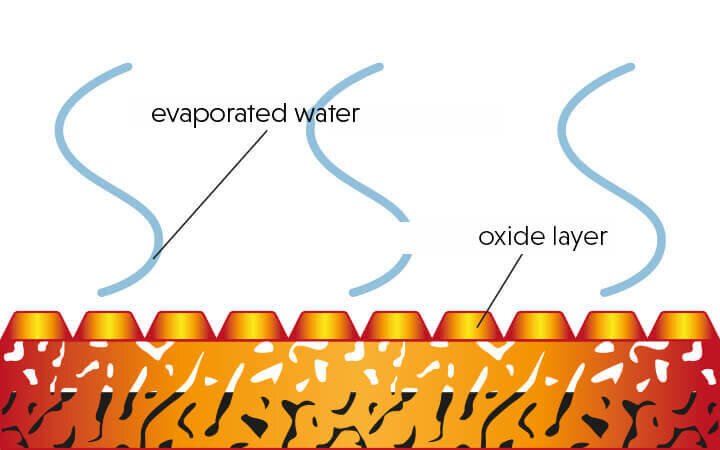

Why does food cooked in OIGEN pans with Naked-Finish taste better? The surface of OIGEN pans with Naked-Finish draws excess moisture from the food's surface while cooking and immediately evaporates it with high surface temperature and radiant heat. This helps to retain the flavor in the food, keeping it tender and juicy inside while making the surface crispy and aromatic.

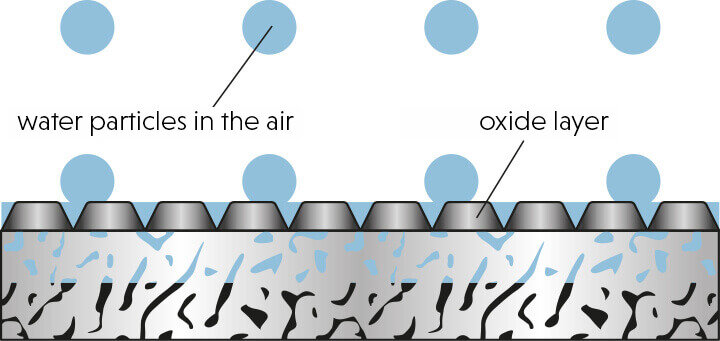

The surface of the pure metal attracts tiny water droplets on its surface, which settle into the gaps left by the burnt carbon. Therefore, the cast iron pan must be heated so that the water can evaporate. After cooling down, the surface is ready to absorb oil. This oil (for example, linseed oil) must be heated in the next step to complete the seasoning process. The addition of vegetables further enhances the seasoning process.

Can lower-quality cast iron pans be heated empty?

The Nonstick Effect. And when it works

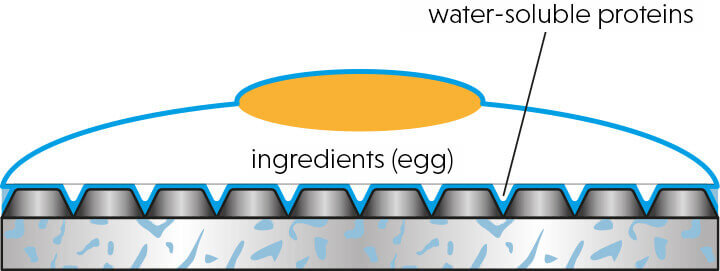

Every food contains water. Water-soluble proteins react with the metal surface when heated, harden, and stick to the pan. An oil layer between the metal and the food prevents sticking. Therefore, during the initial seasoning of the cast iron pans, this oil layer is created. OIGEN cast iron pans are particularly easy to season because the surface is perfectly prepared through the manufacturing process.

What distinguishes high-quality cast iron pans? A scientific insight

Cast iron is not only suitable for cooking at very high temperatures. It is also perfect for delicate, slow cooking and for utilizing the residual heat effect. Therefore, with OIGEN products, you can enjoy the full potential of cooking:

Point 1: The outstanding heat retention of thick cast iron: Naked Pan products have high heat retention. Due to the slow heat absorption, the pan bottom heats up evenly without hot or cold spots.

Point 2: Flavor development through even heat: The pan's temperature hardly changes with the addition of food, allowing you to cook at the exact heat you desire.

Point 3: Cooking with residual heat: After the cast iron pan is removed from the heat source, the pan temperature gradually decreases. This allows the heat to completely penetrate the food, preserving cell structures in the food for better flavor.

A Comparison of Heat Transfer of OIGEN Naked Pan Cast Iron Pans with Conventional Frying Pans

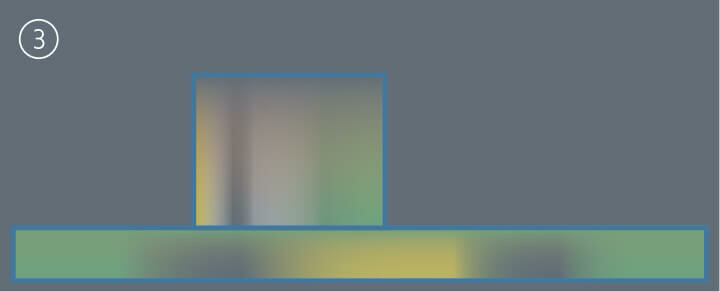

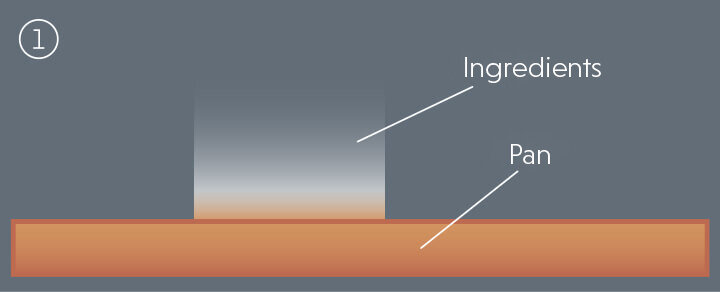

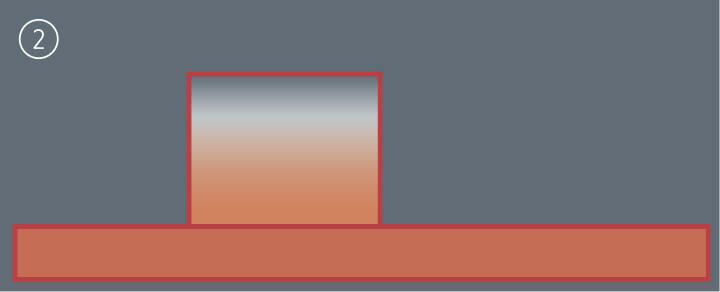

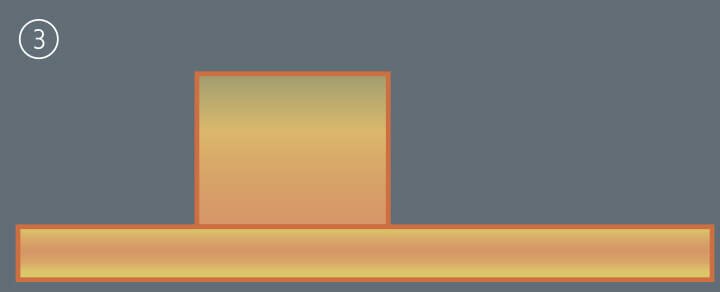

- Heat Transfer of Naked Pan -

- Heat Transfer of Conventional Frying Pans -

1. The food touches the pan

2. Heat transfer from the pan to the food

3. Cooking with residual heat