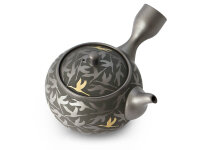

"Tea set Ryusen, Banko Yaki, 4 pieces"

Suigetsu Toen - excellent craftsmanship

Even after more than 300 years, traditional handicrafts in Yokkaichi, Mie Prefecture, continue to flourish in ancient splendor. Banko Yaki pottery has been one of the main pillars of this local culture for centuries. The name Banko is derived from the signature that the founder of the first kiln put on his works. This signature expresses a deep desire that his works be given permanence and enjoyment for a long time. In 1979, Banko Yaki ceramics was recognized by the Japanese Minister of Economy, Trade and Industry as an official traditional craft product of Japan. Today, the teapots made of the \"Purple Clay\" (Shidei-Kyusu) are famous among tea connoisseurs worldwide. Hiroshi Suigetsu tries to balance innovative techniques with his respect for ancient traditions. Thus, he uses conventional methods in manufacturing, but experiments with new techniques in artistic decoration. His excellent work and the many recognitions he has received was the welcome reason for Mie Prefectural Government to declare Suigetsu Toen a Mie Brand.

Teapots and tea bowls made of clay: characteristics, origin and firing method are closely related

The four most important places where Japanese clay teapots were made are Mie Prefecture (Banko Yaki), Gifu (Onko Yaki), Aichi Prefecture (Tokoname Yaki) and Sado Island, Niigata Prefecture (Mumyoi Yaki). In all these areas there are clay deposits with very high mineral content. Ogaki started the production of Japanese clay teapots (Onko Yaki) only in the 19th century. However, this production no longer exists. What has remained, however, is the method he introduced of making Japanese teapots from clay on the potter's wheel. Even in the most important places - Tokoname by far, followed by Yokkaichi in Mie Prefecture - Japanese clay teapots are still made on the potter's wheel by renowned artists. The firing methods used are reduction firing and oxidation firing. While teapots made with reduction firing tend to have a slightly attenuating to neutral character and are recommended for all types of green tea, teapots with oxidation firing tend to intensify the variety of flavors of green tea.

Tokoname Yaki and Banko Yaki

Tokoname and Yokkaichi are probably the most famous places for ceramic products of the highest quality, especially the Japanese teapots. The two cities are located at nearly the same elevation southwest of Tokyo, separated only by Ise Bay on Japan's Pacific coast. The clay from Tokoname is red, while that from Banko is purple (violet) or yellow. Both are very rich in minerals and iron. What are the key differences for tea lovers? Tokoname clay teapots are \"baked\" using either the oxidation process (red teapot) or reduction firing (black teapot). The red teapots are recommended more for mild teas, the black teapots are green tea of any variety very good to good. The purple-colored Banko Yaki is processed at very high firing temperatures, which further activates the already high iron content. The surfaces inside the teapot are usually quite porous, which on the one hand allows the teapot to release minerals to the tea very well, and on the other hand allows ingredients of the tea to be deposited in the teapot, which increasingly leads to flavor enhancement and harmonization with use. Teapots made of Banko-Yaki are especially recommended for high-class, mild tea varieties such as Gyokuro, Kabusecha or noble Sencha.

The advantage of natural clay

The difference between natural and mixed clay is that in natural clay, the iron is in crystallized form. In clay to which iron is \"artificially\" mixed, the iron has been ground beforehand. This process results in a different, uneven and more extensive surface, and the melting point is usually much lower than that of natural iron. And this entails that clay tableware made of clay or loam, to which iron has been added, must be fired at much lower temperatures - about 600-800 degrees - while Japanese teapots made of natural clay can be fired at up to 1200 degrees. This not only increases the strength of the final product, but also the material transformation is affected by the temperature. Most clay teapots today - especially mass-produced ones - from China but also from Japan are made from artificially mixed clay.

Cleaning: Rinse outside and inside with warm water only. Do not use cleaning agents. If necessary, remove contamination with infused green tea. Use creates a tea patina that you do not need to remove, as it gives the teapot its own character.