Japanese Knives

Hand-forged Chef Knives from Japan - a Tradition of Passion

The land of the rising sun is a land of contrasts, which many do not perceive as such. High tech and tradition coexist harmoniously. The same people who admire advanced robotics also appreciate traditional craftsmanship and swear by products made by masterful hands using ancient manufacturing techniques. Japanese knives are a very good example of this. Of course, there are also Japanese chef knives that are produced industrially. However, very often, the passion for good cuisine goes hand in hand with the passion for a hand-forged Damascus knife or a Kuroshiage from a Japanese master forge.

Even in Europe, these high-quality kitchen knives have long found their fan base. And the number of enthusiasts continues to grow year after year. Japanese kitchen knives can be found in professional gourmet kitchens as well as in private households today. Even people who don't spend much time in the kitchen are drawn to the allure of a Damascus knife once they've held it in their hand. Some even develop a collector's passion for these kitchen knives.

And the lively exchange of experiences on internet forums is evidence of sustained interest: Is the versatile Santoku knife – one of the most well-known and popular Japanese chef's knives and often the entry point – the right choice, or do you opt for a Nakiri knife, specially designed for vegetables? Which steel is truly the best, Damascus steel, VG-10, Aogami, or Shirogami? Is "hardness" the only salvation for Japanese blades? So many questions. We're happy to provide an initial overview here.

What Makes Japanese Knives of the Highest Quality So Special

Many people, when they think of a Japanese kitchen knife, often associate it with the venerable samurai and their swords (katana). However, the connection between kitchen knives and samurai swords can be reduced to two points: a love for the sharpness of the blade and the art of wielding that blade. It's worth noting that it was a chef named Hocho who elegantly wielded his Japanese kitchen knife in front of a king and significantly influenced its development. But there is still a connection: the craftsmanship that was first developed through the razor-sharp swords is a rich source of experience for Japanese kitchen knife manufacturers.

What truly sets Japanese kitchen knives apart? Why do many chefs and "specialists" consider these kitchen knives to be the best in the world? The topic cannot be exhausted here, but a brief overview of the pros and cons could be sufficient to help decide whether the new kitchen knife should come from the hand of a Japanese master or from European production.

In particular, they attribute this to the fact that European manufacturers often prioritize less important factors for fans of these kitchen knives: dishwasher compatibility, corrosion resistance, fracture resistance, inexpensive sharpening materials, etc. And in doing so, they have lost sight of essential characteristics such as sharpness, cutting performance, ease of use, and gentle cuts, among others. And that brings us to the heart of the matter, or rather, the heart of the knife: the steel.

Japanese Chef Knives and Their Heart, the Steel

A European kitchen knife must not rust. A Japanese kitchen knife should not rust and is therefore treated with more care. However, Japanese kitchen knives are not entirely uncompromising. What types of steel are processed and, of course, also manufactured in Japan by knife makers?

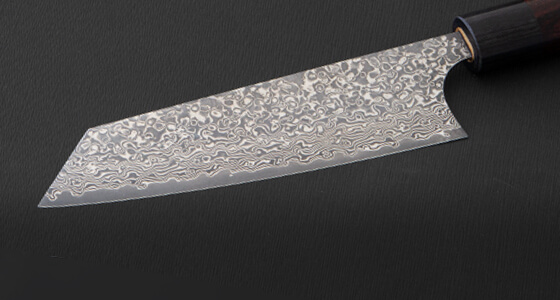

Damascus Steel: Sharp, Durable, Flexible

The most famous steel is Damascus steel or Damask steel. This steel has been used in both weapon and knife production. It consists of high-carbon, very hard steel and lower-carbon, softer steel. The different types of steel are forged together, creating layers and a surface finish that has captivated many fans of Japanese kitchen knives. Japanese kitchen knives with the following characteristics are made from Damascus steel:

- fine Japanese, handcrafted chef's knives

- not entirely stainless

- high hardness (up to over 65 HRC)

- very high sharpness possible

- easy to sharpen

- high durability (cut-resistant)

- relatively flexible

- relatively break-resistant

Aogami I, II, Super: extremely hard, extremely sharp, very cut-resistant

Aogami, blue paper steel, is one of the most commonly used steels for authentic Japanese chef's knives. Blue paper steel is low alloyed, characterized by a very high carbon content of up to 1.4%, and contains traces of chromium (about 0.3%) and tungsten (about 1.1%). What is remarkable and special is the structure of the steel - fine carbides, the finest martensite - which we also find in Shirogami. The properties resulting from these components and the manufacturing process are as follows:

- fine Japanese, hand-forged knives

- not stainless

- very high hardness (up to 66 HRC)

- extreme sharpness possible

- easy to sharpen

- very high durability (cut-resistant)

- relatively inflexible

- lower break resistance (avoid leverage)

Shirogami: uncompromisingly hard, extremely sharp, very high cutting durability

Shirogami is completely uncompromising. White paper steel has many similarities with Aogami but is an unalloyed, pure carbon steel. Its carbon content also goes up to 1.4%, and it lacks tungsten and chromium. Its structure is very similar to that of Aogami. This carbon steel, also popular in Japan for tools and Japanese chef's knives, is often used for specific blade shapes (Honyaki, mostly single-sided ground) and applications, as well as a component of Damascus steel (cutting core). The wear resistance of Shirogami is slightly lower compared to Japanese knives made from Aogami because this steel does not contain tungsten. Hand-forged knives made from Shirogami (excluding Damascus knives) offer the following properties:

- fine Japanese, hand-forged knives, mostly single-sided ground

- not stainless

- very high hardness (up to 65 HRC)

- extreme sharpness possible

- easy to sharpen

- very high durability (cut-resistant)

- inflexible

- prone to breaking

VG-10: hard, sharp, and durable

Stainless steel VG-10 is a high-performance steel but also a compromise. The carbon content is lower, but VG-10 contains a high percentage of chromium (14.5 - 15.5%) and is consequently stainless, but it is also equipped with lower hardness. It's worth noting that this hardness is still significantly higher than the hardness levels of European kitchen knives (52 - 58 HRC). And it should be noted that according to Rockwell, an increase from 58 HRC to 62 HRC means an increase of 46% in hardness. So, a Japanese blade made of VG-10 steel is a compromise, but a very good one. VG-10 is also a popular and excellent material as a cutting core for Damascus knives. The properties of blades made from VG-10 steel can be categorized as follows:

- fine Japanese knives, hand-forged

- stainless

- high hardness (up to 61 HRC)

- high sharpness possible

- easy to sharpen

- high durability (cut-resistant)

- relatively flexible

- low tendency to break

Japanese Knives - the shapes of desired properties

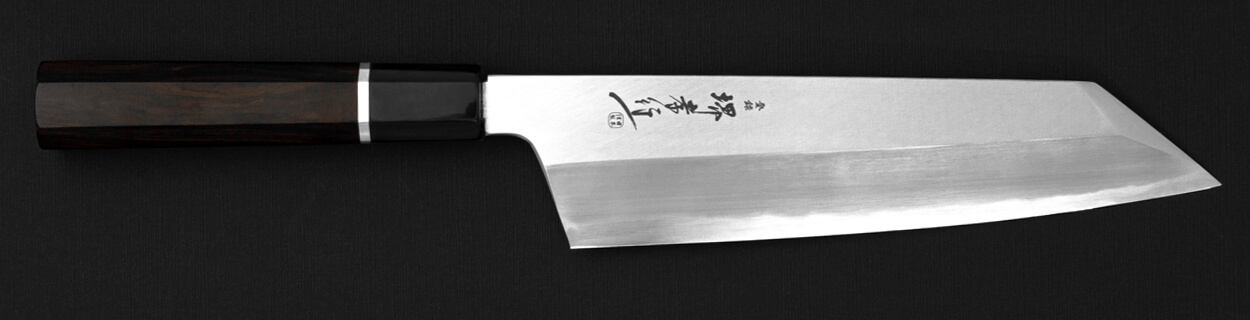

Time and time again, you hear: these knives just look classy. However, this was never the intention in the development of Japanese kitchen knives. Shibata Takayuki, one of our partners in Fukuyama, clearly states that he places much higher importance on the art of creating a knife that is as perfect as possible for the user, rather than the appearance and design of the knife. Original Japanese knives are clearly developed to achieve an optimum level of comfort and results for the price.

The comfort lies not in being able to put a valuable Japanese Damascus knife in the dishwasher but in the extraordinary cutting performance. The better results are not only faster cutting with less effort, but also gentler cutting, as Japanese knives "destroy" significantly fewer cell structures, resulting in a smoother cutting surface.

A small angle makes a big difference

High-quality hand-forged blades owe their excellent cutting performance to the often overlooked fact that they are ground differently. This is only possible because the knife steel used creates the conditions described above. Western kitchen knives have an angle of 40 to 50 degrees. However, usually, half of this angle, 25°, is indicated. This large angle is also due to the typical, "casual" use of a chef's knife.

Japanese kitchen knives are ground at significantly smaller angles, up to 12°. From the perspective of a professional from Japan, a kitchen knife from the Western world is more of a splitting tool.

Santoku Knife - the most popular Japanese chef's knife

Santoku means "three virtues"; it is the all-purpose knife of Japanese cuisine for meat, fish, and vegetables. Santoku knives are a good and right start. The wide blade of the Santoku offers very good guidance. The Santoku corresponds in its use to what we typically call a chef's knife.

Gyuto - the versatile Japanese kitchen knife

Slicing, filleting, and preparing fish and meat - all of these tasks can be done with the Gyuto. It is usually slightly longer than, for example, the Santoku. The tapering of the Gyuto is slightly less pronounced than that of the Santoku, making it even easier to cut through meat.

Nakiri and Usuba - vegetable knives

The Usuba is single-sided ground, while the Nakiri is double-sided, making it a vegetable knife suitable for both right and left-handed users. The shape is determined by the wide blade and straight edge. This allows for easy cutting of large vegetables. The wide blade enables precise guidance along the back of the fingers, making it easy to create beautiful, narrow strips or slices.

Ajikire - this Japanese chef's knife fillets small fish

For those who want to fillet small fish like mackerel, the Ajikire is the choice. Other uses include cutting herbs, cleaning salads, or vegetables. The Ajikire is similar to the Deba but has a wider spine.

Sashimi Sujihiki or Yanagiba - Its Specialization is Filleting Fish or Meat

The Yanagiba (single edge) and Sujihiki (double edge) are often used with a "pulling cut," much like when filleting fish, meat, or even slicing ham. It is similar to the European ham knife but offers some advantages. If you've ever watched a sushi master at work, you've probably witnessed the artistry with which they use the Japanese Yanagiba knife.

Deba Knife - It Cuts Fish but Is Also Suitable for Light Chopping

The Deba features a relatively thick-walled, robust blade but is usually very sharp. When cutting fish, its robustness allows it to cut through bones with ease.

Petty - The Japanese Peeling Knife

The peeling knife, Petty, is actually a smaller all-purpose knife with versatile uses. It's very handy and should always be on hand for quick tasks. In the West, it's often called a paring knife or utility knife.

Bunka - The Classic Japanese Multipurpose Knife for Fishermen

It was specifically developed for fishermen. It has a balanced knife shape, easy to handle, relatively short but precise. The Bunka is symmetrically ground and a typical all-purpose knife. It's quite similar to the Santoku knife, although the Santoku knife is more popular in Europe.

Funayuki - The Fine Deba Knife

The all-purpose Funayuki knife is similar to the Deba, suitable for fish filleting but much finer, with a narrower spine. This makes it more versatile. The Japanese Funayuki knife is also a basis for the more Western-influenced Santoku knife.

Japanese Knives and How to Care for Them

It has already been mentioned that a good kitchen knife - hand-forged and sharp - has no place in either the dishwasher or the wet sink. Good cooking in Japan is also closely related to how the dishes look on the beautiful plate. Therefore, cutting plays an important, if not fundamental, role. The chef does not chop, lever, or twist the knife. A kitchen master who values their tools will never throw them unprotected into a drawer, where they can slide uncontrollably and collide with other utensils. Of course, you should clean the valuable Damascus knife as thoroughly as a rustic Kuroshiage, dry the delicate sharp knives carefully, and store them in a dry place. Here, you can learn more about cutting techniques and the proper handling of Japanese knives.

Even though the knife blades maintain their sharpness for a long time, they should be sharpened carefully and thoughtfully on a whetstone when needed. A Japanese kitchen knife should never touch a honing steel - it gets its edge with a wet Japanese whetstone, and the finishing touches are done with a fine-grit whetstone. A little knife oil can be used to quickly and easily maintain the handle and blade.

The Oryoki Range for Japanese Kitchen Knives

We have carefully considered how to best design the offering for Oryoki customers. True to our philosophy, we naturally focus on craftsmanship. As passionate individuals, we searched for the best Japanese knives and their manufacturers. And since we are fans of good design, it's no surprise that we have succumbed to the allure of Damascus steel. Damascus steel was and is a must. The “black-forged” Kuroshiage knives have also captured our hearts. Ultimately, our small range goes from excellent, hand-forged Damascus knives to a sensible, high-quality entry, which means real Japanese knives that can bring long-lasting joy to cooks and chefs. Eight partners have convinced us with their offerings, skills, and passion:

Kanehiro, Echizen Uchihamono

The Kanehiro forge is world-famous, primarily because of its "venerable" master blacksmith Hiroshi Kato. He is considered one of the masters with the most experience in making Hocho - Japanese kitchen knives. Born in 1941 and trained by his father, he has been forging the finest Kuroshiage and Damascus knives since 1960. In 1993, he and other master blacksmiths in the field founded a cooperative in the knife village of Takefu with the goal of promoting collaboration between the old masters, sharing knowledge and experience, and making it available to the next generation. This was a novelty, as until then, the masterful secrets of how to forge the best Japanese kitchen knives were mostly kept within the family.

Kato-san is described as the leading figure in this community who, despite his old age and long experience, has never stopped improving his technique and products. The Kanehiro forge was founded in 1953 by Kintaro Kato and today offers Japanese kitchen knives, Western knives, special knives, and sickles, all under the guidance of Hiroshi Kato. Just as Yoshimi Kato was trained by his father, Yoshimi Kato learned his masterful craft from Kato-san and followed in his footsteps. He was born in 1969, and most of Kanehiro's knives now come from his hands. From Yoshimi and Hiroshi Kato, we currently carry five handcrafted knife series in our range: “Yoshimi Kato Rose Ebony Damascus Hammer Finish”, “Yoshimi Kato Kuroshiage Nami”, “Yoshimi Kato SG2 Olive”, “Yoshimi Kato Nashiji”, and “Yoshimi Kato Kurosome Damascus” with 30 layers, each with a noble handle made of different types of wood. Handle with care, they are very sharp!

Shizu Hamono

The synergy of enthusiasm and technology, the use of traditional techniques in new product areas. Shizu is a relatively young company that does not exclusively deal with kitchen knives. Shizu is located in Seki, a traditional knife - or rather, sword - city. Swords have been forged here for over 700 years. A very good basis for the production of Japanese kitchen knives. We carry two knife series from Shizu, which, although fundamentally of traditional quality, have a more modern design. The series are called “Yamato” (with 3 layers) and “Yuri” (with 3 layers). Each series includes a Santoku knife, a Yanagiba, a Nakiri, a Deba, and a Petit, which corresponds to the Petty knife. The knives are all made of stainless steel. We also offer the practical combination whetstones from Shizu in our range.

Nigara Hamono

The sword and knife forge Nigara Hamono can look back on a tradition of over 350 years. The forging techniques used by Nigara are essentially the traditional art of forging that has been used for centuries to produce high-quality sword and knife blades. Folding and hammering soft iron and steel creates a distinctive beauty in every knife made by Nigara. The blades usually stand out due to their distinctive hammering. We carry, among other things, the series with blades made of blue paper steel “AS Kiritsuke Tsuchime”, as well as the series with black-forged SPG2 blades and Wenge handles “Kuroshiage Tsuchime”.

Yoshida Hamono

Yoshida Hamono belongs to the traditional blacksmiths known as "Field Blacksmith" on the island of Kyushu. The term originated in ancient times and stands for local support, where many high-quality and useful tools were made or repaired for daily life. The craftsmanship was passed down from generation to generation and constantly improved and expanded. This results in hand-forged kitchen knives of the highest quality and long life today. In our range, we have a series with a blade hardness of 66 - 67 HRC “Damascus Kyusakichi ZDP189”, which is forged from ZDP-189 stainless steel, as well as the series with 69 layers of Damascus steel “Damascus Kyusakichi ZA-18”.

Aoki Hamono, Sakai Takayuki

Aoki Hamono brings together the masters of traditional knife art to preserve the 600-year-old tradition of knife making in Sakai and pass it on to the next generation. SAKAI knives have a very high standard of quality and enjoy an excellent reputation in Japan and around the world. Particularly noteworthy are the “Homura Kengata Series” by master blacksmith Itsuo Doi san and the “Silver Steel Damascus” series by master Suogo Yamatsuka san.

Tips for Maintenance and How to Sharpen Japanese Knives

High-quality, handcrafted knives should be properly cared for to preserve their appearance and functionality. We provide you with tips on what to consider to ensure your knives bring you joy for a lifetime. Here, you will also find our practical sharpening guide with an authentic Japanese whetstone. Available as an article and for download:

On our YouTube channel, you will find a video tutorial on how Japanese masters sharpen knives on a Japanese waterstone.