"Damascus knife Sujihiki 270 SG2, 63 layers, olive"

Yoshimi Kato - Master in the tradition of the family knifemaking

Yoshimi Kato leads the family knifemaking business as a master craftsman and has proven himself a truly worthy successor to his grandfather Kintaro Kato and his father Hiroshi Kato. Like his father and grandfather, he walked the long and intense path to becoming a master of the high art of knifemaking and has mastered his craft to an exceptionally high level. Hiroshi Kato once co-founded the knife village Takefu together with other master blacksmiths. The aim was to preserve the old knowledge, exchange experience and pass it on to young blacksmiths. Yoshimi Kato continues this legacy and has taken the art of knifemaking to new heights. Although traditions play an important role in the family, Yoshimi Kato is also a person of change and evolution. His knives are finding more and more enthusiastic customers in Japan as well as in Europe. They are distinguished by the superbly crafted production of the blades, the well-considered choice of knife steels, high-quality handles, very good balance of the knives and high design quality. We thank Yoshimi for the trustful and creative cooperation.

Knife Series Yoshimi Kato Damascus Knife SG2

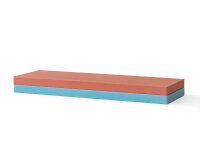

Material: The chef's knife series Damascus Knife SG2 forges Yoshimi Kato, as the name suggests, from SG2 steel. This powder steel was developed explicitly for Japanese knife blades and produced by several manufacturers. Therefore, there are also several names for the approximately same steel: SG2, SGPS, SPG2, Super Gold 2, Super Gold Powder Steel. Yoshimi Kato obtains the steel from Takefu Special Steel, the original designation is SPG2 Super Gold 2. It is a high quality stainless steel with high hardness and excellent cutting performance. Basically, the steel has the following elements: carbon, which affects the hardness of the steel, chromium, which increases corrosion resistance. Molybdenum and vanadium are alloying elements that have a positive effect on strength and wear resistance of the steel. It is important to note that SG2 is a very high quality steel, which is also usually more expensive than other common steel grades for knife blades, such as VG-10, but the cutting performance and durability of SG2 knives are also higher. If the steel is heat treated accordingly, a hardness of about 63 HRC is achieved. The sheath is made of nickel damascus in 62 layers, so in total the blade has 63 layers. Finish: Visually, the blade is of course dominated by the Damascus layers. For additional protection and a special design, these knives are burnished, which emphasizes the noble appearance. Handle: We offer this series with two different handles. One handle is made of Italian olive wood, waxed and shaped octagonal (octagon). The other handle is made of Japanese quince wood, octagonal (octagon). Both handles give a great feel and lie superbly in the hand.

How to use

Japanese chef's knives are made of extremely hard steels and are forged and ground thinner than their European counterparts. Some of these knives have very finely ground cutting layers, making them more delicate and suitable only for soft cut foods. Please refer to the product details for information in this regard. In particular, knives with a very thin cutting edge and hollow grind are prone to chipping on the blade. These are excellent for fine cuts of soft cut material, but should be used with appropriate care. Sharpening on a whetstone usually produces an angled grind, which makes the edge more stable over time.

Breakouts on the cutting edge can also occur due to leverage forces as well as frozen cuttings, which significantly reduce the temperature of the steel. Leverage forces often occur when cutting material with bones, for example. Chipping on the cutting edge may need to be ground out by a professional.

The knife should always be guided straight with pulling or pushing cut, without much pressure. To maintain sharpness, avoid cutting on stone, glass or other hard surfaces. Never use \"sharpening steel\" for resharpening. Water sharpening stones are recommended (grit: 400-1200 for preliminary sharpening, 3000 for fine sharpening, 6000 or more to strip the blade) and a honing leather if necessary.

Please keep the knife away from children. These knives are extremely sharp, please be careful.

All products are unique, so slight deviations from the exemplary picture are possible.

Care instructions

When using knives made of delicate steel types, such as Aogami, Shirogami or V-Toku, please clean them occasionally with a cloth and water even during prolonged use. However, acidic foods can still cause discoloration on these classic carbon steels. After use, please wash by hand with hot water and use a neutral detergent if necessary. Please do not put the knife in the dishwasher under any circumstances. After cleaning, dry thoroughly, oil if necessary, and store in a well-ventilated area. Residual moisture can cause rust in non-stainless steels. See our posts on the ORYOKI Japan blog for product care.

Clean the knife by hand and do not use a dishwasher. Dry it thoroughly afterwards.