Kanetsugu Cutlery, the knifemakers from Seki

The company Kanetsugu Cutlery was founded in 1949. It emerged from Kawamura Matsujiro & Co., which had been producing Japanese chef's knives since 1918. Both companies were managed by Matsujiro Kawamura. The tradition of the company goes back to the Nanboku-cho era (1336-1392) when a first Kanetsugu became a swordsmith. Mitsuyasu Kawamura became president of Kanetsugu in 1994 in the third generation. This makes Kanetsugu one of the knife producers with the longest family tradition in this trade. The company is based in Seki-City, the capital for knife production in Japan.

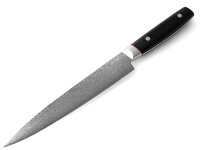

Messerserie Saiun

Die Messerserie Saiun verbinden moderne Komponenten mit klassischen, japanischen Messerklingen. Die Klingen haben einen Schneidkern aus dem hochwertigen Kohlenstoff-Edelstahl VG-10, der sehr rostresistent ist. Mit einer Härte von 60-61

HRC übertrifft dieser japanische Stahl von Hitachi Metalls die meisten Edelstähle. VG-10 ist zu einem der am meisten verwendeten Edelstähle in Japan für Damastmesser geworden und zeichnet sich besonders durch seine Härte, Schnitthaltigkeit und Korrosionsbeständigkeit aus. Ummantelt sind die Messerklingen mit 32 Lagen Damast in 32 Lagen. Die Griffe der Saiun Messerserie bestehen aus schwarzem Micarta, harzimprägniertes Holz mit Leinen. Dieses Material ist sehr unempfindlich, langlebig, wasserabweisend und pflegeleicht. Für den Schliff sind die Messer von Kanetsugu bekannt. Alle Saiun Messer sind leicht konvex geschliffen, was den Klingen Stabilität, Haltbarkeit und ein überaus angenehmes Schneidverhalten gibt. Dieser Schliff leitete die Kanetsugu Cutlery aus den traditionellen japanischen Schwertern ab, die der Schwertschmied Kanetsugu bereits im 14’ten Jahrhundert schmiedete.

Instructions for use

After use please wash by hand with hot water. If necessary, use some neutral detergent. The knife should not be put in the dishwasher. Dry well after cleaning. Please keep the knife away from children. These knives are extremely sharp, please be careful. Japanese chef's knives are made of very hard steels and are forged thinner than European knives. Please make sure that no unnecessary forces - especially no lever forces - act on the blade, otherwise small chipping may occur in the blade. These may have to be ground out by a specialist. Leverage forces often occur when cutting deep-frozen material or bones. The knife should always be guided straight and cutting, without much pressure. To maintain sharpness, the knife should not cut on stone, glass or other hard surfaces. Never use "sharpening steel" for resharpening. We recommend using water grinding stones (grit: 400-800 for pre-sharpening, 1000 or considerably more for fine grinding).

blade type:

peeling knife

Manufacture/Smith

Seki Kanetsugu Cutlery

Materials

blade: VG-10, stainless steel. 32 layers of damascus steel. Handle: Micarta

blade hardness

60 - 61 HRC

Grinding

Ryo-ba (both sides)

Dimensions approx.

blade length: 85 mm

blade height: 21 mm

blade thickness: 1.7 - 0.4 mm

total length: 195 mm

weight: approx. 74 g

packaging

cardboard packaging

Care

Clean by hand, no dishwasher. Dry thoroughly.