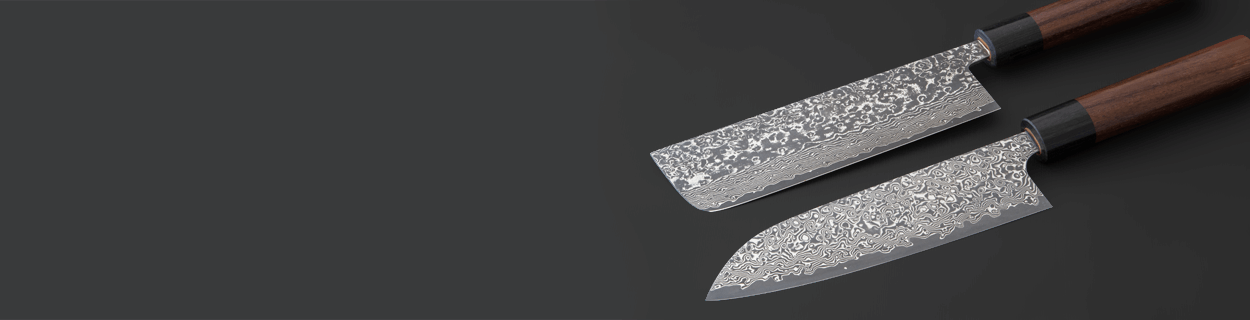

Japanese Damascus Knives

Damascus Knives or a Dubious Compromise

In ancient times, the lack of homogeneity - even distribution of different components in the base material - due to imprecise iron production played a significant role in the manufacture of knives or swords. Folding and forging improved the material's homogeneity and expelled unwanted components. However, this problem is a thing of the past. Today, steel grades with precise components and resulting properties are manufactured. These range from unalloyed steel, such as Shirogami, to low-alloyed steel like the popular knife carbon steel Aogami, to highly alloyed stainless steels.

The production of kitchen knives in the western world has heavily focused on a compromise solution: stainless steel. It offers sufficient flexibility, acceptable sharpness and edge retention, and, due to its low susceptibility to rust, a "comfort" that is highly appreciated. This comfort mainly consists of the fact that kitchen knives made of stainless steel can tolerate moisture better - the knives do not rust - and are less prone to breakage. These knives are considered "easy to care for" because they are not truly destroyed in either the dishwasher or the "mass storage" drawer.

However, it is often forgotten that kitchen knives made of relatively soft stainless steel quickly lose their sharpness - especially in the dishwasher - and therefore, if one wishes to work with sharp knives, they must be sharpened much more often than knives made of carbon steel or Damascus knives. In general, this means much more effort than simply washing and drying a knife.

Damascus Kitchen Knives - What exactly is a Damascus knife?

What is commonly referred to as a Damascus knife nowadays are chef's knives - or other types of knives - that are made from multiple layers of different types of steel. These layers are the Damascus.

Consistently, chef's knives with 3 layers could already be called Damascus knives. To achieve the desired properties, carbon-rich steel and low-carbon steel are usually combined - in Japan, VG-10 steel, a very high-performance stainless steel, is often used. The hand-forged Japanese chef's knives at Oryoki are made from a combination of VG-10 stainless steel and high-quality Japanese nickel Damascus steel. The layering of different steels creates the visible pattern, and the combination of the steels - hard VG-10 steel and tough nickel Damascus steel - determines the overall blade properties.

The artistry of the master smith lies in optimally combining the two types of steel. The entire production process is very labor-intensive, and the quality of Damascus steel blades depends greatly on the skill of the smith and their experience, as incorrect temperatures can lead to unintended chemical reactions and negatively impact the quality of the Damascus.

The appearance of the blade also provides a clue as to whether the Damascus chef's knife comes from the hands of a master smith. However, contrary to the often-held belief, it is not the number of layers that indicates the particularly high quality of the Damascus steel blade. To the expert, clear indications of the quality of the smith's work can be found in the pattern formed by the Damascus layers.

Is a Damascus knife the better chef's knife?

Yes, provided that certain conditions are met. We base this assessment on the assumption that an optimal chef's knife should have very high sharpness and edge retention. Its resistance to breakage should be so high that, with careful, typical use, breakage is almost impossible. What importance do the different properties have when evaluating a Damascus steel chef's knife?

Layers, Layers, Layers:

In our opinion, the number of layers provides only insufficient hints about the utility of a kitchen knife made of hand-forged Damascus steel. While the raw number may indicate the effort put into making the Damascus knife, it does not say much about how well a Damascus chef's knife performs. As far as the artistic component is concerned, the number of layers is somewhat more informative. However, even a simple look at the Damascus blade can provide qualitative insights to experts, but these may remain hidden from relative novices.

Material, Steel:

Undoubtedly, an important criterion for evaluating Damascus knives, especially since the material not only brings the aforementioned properties but also provides the master smith with important possibilities for how the Damascus blade can be forged. A high-quality blade can generally be forged thinner, which brings significant advantages in terms of effort and potential damage to the cutting material, especially for a chef's knife.

Blacksmithing:

Ultimately, the quality of a blade made of Damascus steel is determined by the blacksmith. Even very good material can be poorly processed. Especially with Damascus knives, poor craftsmanship, which could manifest itself, for example, in inadequate bonding of different types of steel, cannot be rectified. Unfortunately, we have not yet found any indications of how a layperson could objectively assess this criterion. Therefore, we attach great importance to the origin of hand-forged chef's knives, as we assume that the renowned blacksmiths in Japan and beyond simply do not want or cannot afford Damascus knives of poor quality. Why would they? Even a poorly forged Damascus steel blade with many layers requires significant effort.

Price:

A high-priced, hand-forged Damascus chef's knife from an experienced Japanese blacksmith is something very special. A cheap, hand-forged Damascus chef's knife from Japan should be viewed very critically, despite understanding the desire for a bargain. There are several reasons why such a Damascus chef's knife may not have been truly crafted in a high-wage country like Japan by skilled hands. Even the "better purchasing conditions" of a large provider are not a valid argument, as these skilled craftsmen are relatively scarce and cannot produce masses of Damascus knives by hand to achieve a very low price for such a kitchen knife.

The Art and Beauty of Damascus Knives in Our Collection

Damascus knives are not only well-known, but they are also extremely popular. At least in part, this is surely due to the beautiful appearance of Damascus knife blades, which are quite exceptional with their decorative wave patterns. The Japanese knife with a Damascus steel blade bears a resemblance in appearance to the ancient Japanese swords, Catania, which were also made with Damascus blades. It is customary in Japan to equip traditionally crafted Damascus knives with wooden handles. The handles are usually made of high-quality and durable rosewood (palisander) or cherry wood. We offer some very sharp Damascus steel knives in our range. Our assortment covers all knife shapes needed in the kitchen, from the multipurpose Santoku knife to the specific vegetable knife Nakiri.

Which Damascus Knife is the Right Choice?

Two criteria should be met by the chosen Damascus knife:

- Appearance: High-quality, hand-forged, Japanese Damascus knives are not really cheap. Since the effort to produce them is enormous, these kitchen knives generally belong to the most valuable acquisitions. Thus, the selected Damascus knife should also convince with its design.

- Function: The purpose of intricately forging Japanese knives from multiple types of steel is to harness the benefits of the different steel types. The softer cutting core provides the knife with flexibility, while the Damascus exterior, the laminate, is made of very hard steel with very high sharpness potential. These high-quality knives can be sharpened extremely sharply and retain their sharpness for a long time (high edge retention).

Accessories for Japanese Damascus Knives

Even with the highest edge retention of the hard Damascus blade, the Damascus chef's knife must eventually be sharpened. Of course, there are "professionals" in Germany who offer to sharpen Japanese Damascus knives as well. However, this is often a task that the enthusiast of a high-quality Japanese Damascus knife would like to do themselves. But let's start from the beginning: What things should be considered and available when one has decided on a Damascus knife?

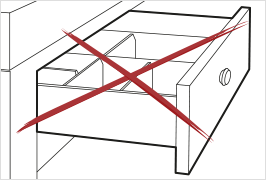

Storage of Knives:

Japanese knives should never be stored in a drawer where they constantly collide with other hard objects. Whether the kitchen knife is simply stored in its packaging or in a beautiful knife block is secondary. The main thing is that the Damascus knife remains separate and the Damascus blade comes into contact with other metal objects as rarely as possible.

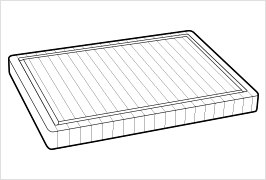

Cutting Board:

If the surface on which cutting is done is too hard - marble, stone, glass - this will damage Japanese knives. Even bamboo, a popular material for cutting boards, is borderline, with some knife manufacturers in Japan advising against it. Plastic or wooden cutting boards do not damage the knife. However, when making a selection, one should consider that with plastic cutting boards, there is a risk of transferring tiny plastic particles to the food with the knife. Regardless of the type of knife used and how sharp it is.

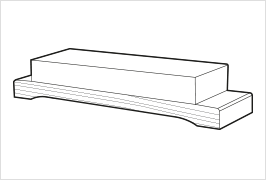

Sharpening Stone:

To periodically sharpen the kitchen knife, a sharpening stone is required. For hand-forged, Japanese knives, sharpening steels should definitely be avoided. Also for Damascus knives. An water sharpening stone with the right grit or a combination stone with two different grits is ideal. It is advisable to sharpen the knife in multiple passes: preliminary sharpening with relatively coarse grit if the knife is very dull, 1 - 2 times fine sharpening with finer grit. Please refer to the specifications for each knife.

Damascus Knife - Damascus or Damascus Steel

Damascus steel is a material made of multiple layers of steel of one or different types of steel. The steel layers were and are firmly joined together by various methods. In Europe, Damascus steel mainly refers to a composite steel created by welding. Other methods include, for example, the crucible steel process from the Orient. According to our research, the original Damascus steel for Damascus weapons was made. So not by welding or forging, but already by the melting process. Damascus steel was primarily invented for the production of edged weapons, the blades of which were subjected to particularly high stresses and had to meet very specific requirements.

The term Damascus steel is derived from "Damascus" because the Damascus steel imported from the Indian-Persian region to Europe in earlier times or products made from it took their route via Damascus. Damascus was not the place of manufacture of Damascus but the trading metropolis where Damascus steel or the weapons made from it were traded.

Iron or Steel and What's the Difference

Iron is a chemical element and steel is an alloy. Iron is the main component of steel, along with a number of other trace elements which, depending on their content, more or less strongly influence the properties of the material. The desired result of iron or steel production should be a material that is as homogeneous and forgeable as possible, can be strongly hardened, does not easily bend, and certainly does not break easily.

The hardenability of iron or steel is very much related to the carbon content present in the material. However, carbon also brings a disadvantage: the material becomes more porous or brittle with a high carbon content, and the blade would break more quickly. A material with less carbon is more flexible but less hard, thus having less potential for sharpness. Moreover, the edge retention, that is, the lower sharpness of blades made of soft steel, also decreases much faster. An attribute that is undesirable for neither a sword nor a chef's knife.

Damascus Knife with Engraving

In general, hand-forged knives from Japan are equipped with the engraving of the master. Usually, it is the "signature" of the master blacksmith. If a Japanese manufacturer collaborates with several blacksmiths, the brand of the manufacturer is usually engraved on the kitchen knife. The engraving is intended as a hint of authenticity of the product, but unfortunately, we have also read about fraud. Especially with cheap bargain offers of Damascus knives with engraving, this should be critically questioned.

Tips for Care:

On our YouTube channel, you'll find a video for instructions on how Japanese masters sharpen knives on a Japanese waterstone.