Kanetsugu Cutlery, the knifemakers from Seki

The company Kanetsugu Cutlery was founded in 1949. It emerged from Kawamura Matsujiro & Co., which had been producing Japanese chef's knives since 1918. Both companies were managed by Matsujiro Kawamura. The tradition of the company goes back to the Nanboku-cho era (1336-1392) when a first Kanetsugu became a swordsmith. Mitsuyasu Kawamura became president of Kanetsugu in 1994 in the third generation. This makes Kanetsugu one of the knife producers with the longest family tradition in this trade. The company is based in Seki-City, the capital for knife production in Japan.

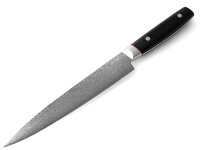

Knife series Saiun

The knife series Saiun combines modern components with classic, Japanese knife blades. The blades have a cutting core made of the high quality carbon-stainless steel VG-10, which is very rust-resistant. With a hardness of 60-61

HRC, this Japanese steel from Hitachi Metalls surpasses most stainless steels. VG-10 has become one of the most widely used stainless steels in Japan for damask knives and is particularly distinguished by its hardness, cut resistance and corrosion resistance. The knife blades are sheathed with 32 layers of damask in 32 layers. The handles of the Saiun knife series are made of black micarta, resin impregnated wood with linen. This material is very resistant, durable, water-repellent and easy to clean. The knives from Kanetsugu are known for their cut. All Saiun knives are slightly convex ground, which gives the blades stability, durability and an extremely pleasant cutting action. The Kanetsugu Cutlery derives this cut from the traditional Japanese swords, which the swordsmith Kanetsugu already forged in the 14th century.

Instructions for use

After use please wash by hand with hot water. If necessary, use some neutral detergent. The knife should not be put in the dishwasher. Dry well after cleaning. Please keep the knife away from children. These knives are extremely sharp, please be careful. Japanese chef's knives are made of very hard steels and are forged thinner than European knives. Please make sure that no unnecessary forces - especially no lever forces - act on the blade, otherwise small chipping may occur in the blade. These may have to be ground out by a specialist. Leverage forces often occur when cutting deep-frozen material or bones. The knife should always be guided straight and cutting, without much pressure. To maintain sharpness, the knife should not cut on stone, glass or other hard surfaces. Never use "sharpening steel" for resharpening. We recommend using water grinding stones (grit: 400-800 for pre-sharpening, 1000 or considerably more for fine grinding).

blade type:

all-purpose knife, Petty

Manufacture/Smith

Seki Kanetsugu Cutlery

Materials

blade: VG-10, stainless steel. 32 layers of damascus steel. Handle: Micarta

blade hardness

60 - 61 HRC

Grinding

Ryo-ba (both sides)

Dimensions approx.

blade length: 120 mm

blade height: 24 mm

blade thickness: 1.7 - 0.4 mm

total length: 225 mm

weight: approx. 81 g

packaging

cardboard packaging

Care

Clean by hand, no dishwasher. Dry thoroughly.