"Damascus knife SPG2 Kiritsuke Gyuto 240, 49 layers"

Nigara Hamono - Since the days of the samurai

The sword and knife smithy Nigara Hamono has a tradition of over 350 years. During the early Edo period, the city of Hirosaki was a castle town. There were over a hundred forges in the area at that time. Nigara Forging is one such historic forge located in Tsugaru, north of Hirosaki, which has preserved and maintained its craftsmanship to this day. The forging techniques used by Nigara are essentially the same as the traditional forging techniques that have been used for centuries to make high-quality sword and knife blades. The folding and hammering of soft iron and steel creates a distinctive beauty in each knife Nigara makes.

SPG2 Damascus Knife Series by Nigara

Your eyes automatically wander to the beautiful blades of this knife series. 48 layers of Damascus steel and a core of SPG2, the Super Gold powder steel. The finish is burnished, which shows off the gorgeous pattern excellently. Of course, Nigara pays attention to a perfect balance, the feeling when you have the octagonal handle in your hand is overwhelming. The hard steel of the cutting core, forged to about 62 HRC, offers excellent sharpening potential. Manufacturer of the steel Takefu, Japan. Depending on the translation, the steel is also referred to as SGP2, Super Gold Powder 2. This steel is an absolute premium steel, very high priced and hard to get even in Japan. This powder metallurgical high performance steel has a very fine structure. The high carbon content of 1.3% makes it extremely hard, so that up to 65 HRC is possible. Other components are 15% chromium, 3% molybdenum and 2% vanadium. With this cutting core, the knives in the series offer exceptional sharpness, cutting performance and durability, surpassing even the premium VG-10 steel. The handle is made of ebony, fits very well in the hand, the ferrule is made of genuine buffalo horn. All in all, the SPG2 Damascus series is a very successful series of knives that will give a lot of pleasure.

How to use

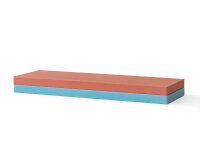

Japanese chef's knives are made of extremely hard steels and are forged and ground thinner than their European counterparts. Some of these knives have very finely ground cutting layers, making them more delicate and suitable only for soft cut foods. Please refer to the product details for information in this regard. In particular, knives with a very thin cutting edge and hollow grind are prone to chipping on the blade. These are excellent for fine cuts of soft cut material, but should be used with appropriate care. Sharpening on a whetstone usually produces an angled grind, which makes the edge more stable over time.

Breakouts on the cutting edge can also occur due to leverage forces as well as frozen cuttings, which significantly reduce the temperature of the steel. Leverage forces often occur when cutting material with bones, for example. Chipping on the cutting edge may need to be ground out by a professional.

The knife should always be guided straight with pulling or pushing cut, without much pressure. To maintain sharpness, avoid cutting on stone, glass or other hard surfaces. Never use \"sharpening steel\" for resharpening. Water sharpening stones are recommended (grit: 400-1200 for preliminary sharpening, 3000 for fine sharpening, 6000 or more to strip the blade) and a honing leather if necessary.

Please keep the knife away from children. These knives are extremely sharp, please be careful.

All products are unique, slight deviations from the exemplary picture are therefore possible.

Care instructions

When using knives made of delicate types of steel, such as Aogami, Shirogami or V-Toku, please clean them occasionally with a cloth and water even during prolonged use. However, acidic foods can still cause discoloration on these classic carbon steels. After use, please wash by hand with hot water and use a neutral dishwashing detergent if necessary. Please do not put the knife in the dishwasher under any circumstances. After cleaning, dry thoroughly, oil if necessary, and store in a well-ventilated area. Residual moisture can cause rust in non-stainless steels. See our posts on the ORYOKI Japan blog for product care.

Clean the knife by hand and do not use a dishwasher. Dry it thoroughly afterwards.