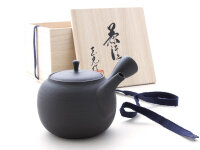

"Cooling bowl Yuzamashi Kuro, 300 ml"

Gyokko - the master of pottery

When it comes to the small teapots Kyusu, he is one of the greats. Master Gyokko has won many awards for his sensitive, delicate craftsmanship: Japan Sencha Art, Choza-Sho Pottery Exhibition, Encourage Prize, the Award of \"Excellent Craftsmen\" and others. His works show beautiful shapes, very high perfection and many beautiful details. All of Gyokko's Kyusu are hand formed by him on the potter's wheel. In addition, the art of \"baking\", i.e. firing the pottery, is particularly noteworthy. Gyokko masters the \"reduction firing\" like no other, with which he produces his unusual, iridescent shades. Thus, in some of his works he achieves exceedingly vivid color plays and color gradients, while others have a homogeneity of color that is exemplary for unique pieces. The clay with a high iron content required for this is a purely natural product: shudei, a red clay with a high iron content. However, the pottery art of Gyokko is also practical: to be able to pour the tea comfortably Gyokko integrates a ceramic sieve with over 400 hand-poked holes, which tea connoisseurs appreciate even more than stainless steel sieves.

Clay teapots: characteristics, origin and firing method are closely related

The four most important places where Japanese clay teapots were made are Mie Prefecture (Banko Yaki), Gifu (Onko Yaki), Aichi Prefecture (Tokoname Yaki) and Sado Island, Niigata Prefecture (Mumyoi Yaki). In all these areas there are clay deposits with very high mineral content. Ogaki started the production of Japanese clay teapots (Onko Yaki) only in the 19th century. However, this production no longer exists. What has remained, however, is the method he introduced of making Japanese teapots from clay on the potter's wheel. Even in the most important places - Tokoname by far, followed by Yokkaichi in Mie Prefecture - Japanese clay teapots are still made on the potter's wheel by renowned artists. The firing methods used are reduction firing and oxidation firing. While teapots made with reduction firing tend to have a slightly attenuating to neutral character and are recommended for all types of green tea, teapots with oxidation firing tend to intensify the variety of flavors of green tea.

Tokoname yaki, Japanese teapots from Tokoname

Tokoname is the most famous and largest of the ancient kilns for clay production. Its good reputation extends far beyond the borders of Japan. In the diverse range of clay products, Japanese teapots play one of the most important roles. A red, natural clay is mined in Tokoname: Shudei. The fact that there are teapots of different colors made of red clay is due to the firing method used, reduction firing or oxidation firing, and the amount of oxygen supplied during firing. The clay governs very sensitively, so that high-quality products succeed only to those who have a lot of experience and tact. The history of Tokoname goes back a long way. As early as the 12th century, the kiln went into operation, making it one of the oldest in Japan. In the early days, Tokoname used white clay obtained from the rice fields. However, around 1954, Sugie Jyumon, together with a doctor - Hirano Chuji - discovered that the natural red clay of Tokoname had an excellent mineral composition. This marked the career of red clay. A special type of decoration typical of Tokoname teapots is called Mogake technique. Its inventor was Ina Chozo, who covered teapots with seaweed before firing them. During firing, the minerals in the seaweed and clay reacted and \"formed\" unique patterns on the surface.

The advantage of natural clay

The difference between natural and mixed clay is that in natural clay, the iron is in crystallized form. In clay to which iron is \"artificially\" mixed, the iron has been ground beforehand. This process results in a different, uneven and more extensive surface, and the melting point is usually much lower than that of natural iron. And this entails that clay tableware made of clay or loam, to which iron has been added, must be fired at much lower temperatures - about 600-800 degrees - while Japanese teapots made of natural clay can be fired at up to 1200 degrees. This not only increases the strength of the final product, but also the material transformation is influenced by the temperature. Most clay teapots today - especially mass-produced ones - from China but also from Japan are made from artificially mixed clay.

Cleaning: Rinse outside and inside with warm water only. Do not use cleaning agents. If necessary, remove contamination with infused green tea. Use creates a tea patina that you do not need to remove, as it gives the teapot its own character.